For the economic use of biological odour sensors, a new platform technology is being developed in the project "Biohybrid olfactory and taste sensory systems" that automatically produces cell-based biosensors. The biosensors could give machines a sense of smell and be further developed for various applications, such as the detection of explosives, the detection of gas leaks or the diagnosis of diseases based on the breath of patients. The project represents a prototypical use case for the Fraunhofer strategic initiative "Biological Transformation", in which the institutes IGB and IPA are increasingly focusing on the combination of biological and technical systems.

Biohybrid olfactory and taste sensory systems

For the economic use of biological sensors, the project "Biohybrid olfactory and taste sensory systems" is developing a technology that automatically produces cell-based biosensors. Such sensors could then give machines a sense of smell and be further developed for various applications, such as the detection of explosives, the detection of gas leaks or the diagnosis of diseases based on the breath of patients. The platform will initially be validated on a product from the Californian start-up Koniku.

In order to enable the targeted development of an economically viable product, Fraunhofer IPA will develop a screening method for the selection of receptors and the reliable automated production of transfected cells. Here, the transfected cells must be cultivated over long periods of time outside the cell culture laboratory.

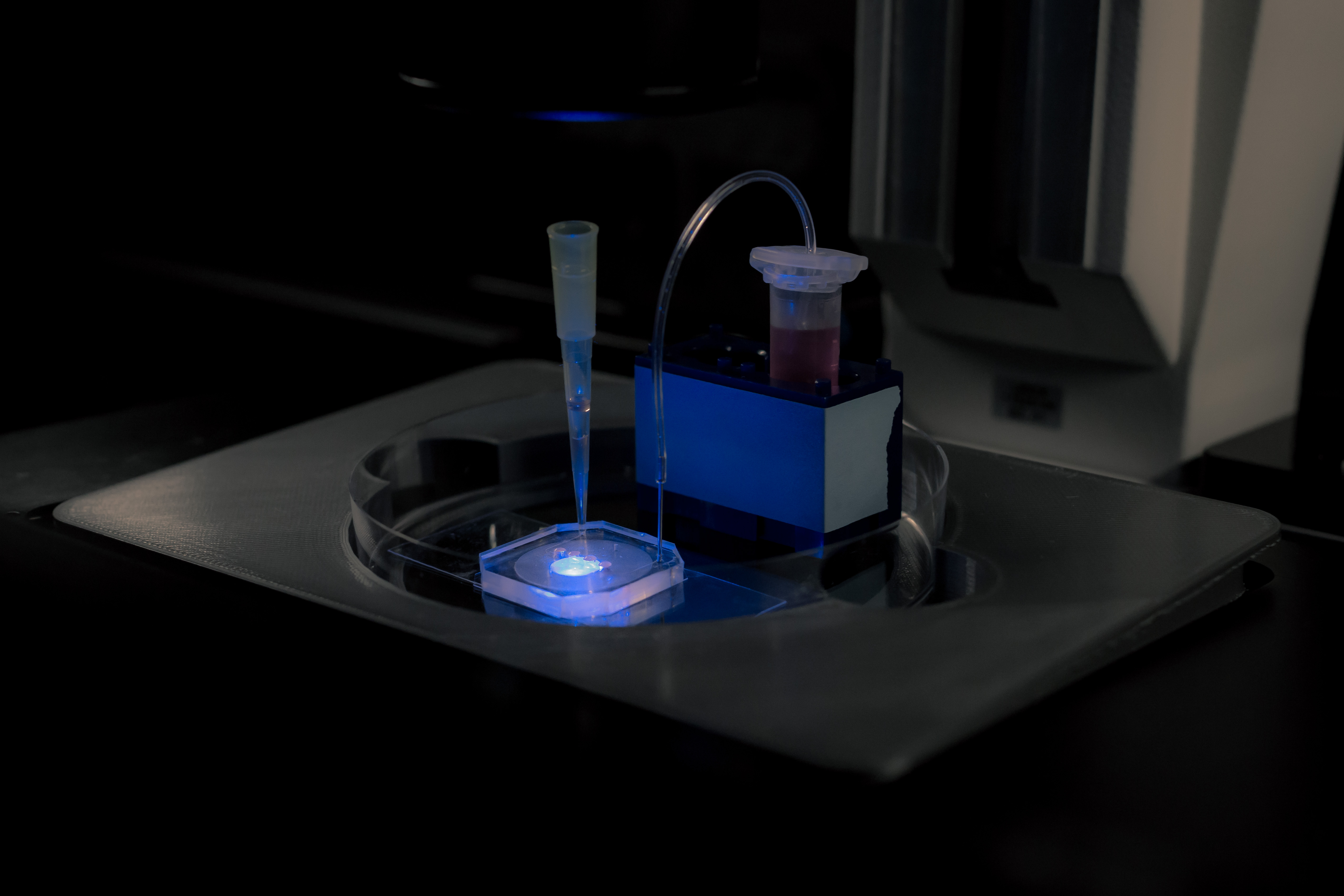

The task of Fraunhofer IGB therefore is to develop a microfluidic culture chamber whose interface to the air is regulated by special membranes. Fraunhofer IGB creates a precisely controllable physiological environment for the transfected biosensor cells by means of microfluidic structures that allow the supply and removal of nutrients or metabolites and enable work with minimal amounts of fluids.

The project represents a prototypical use case for the Fraunhofer strategic initiative "Biological Transformation", in which the institutes IGB and IPA are increasingly focusing on the combination of biological and technical systems.

Project information

Project title

Biohybrid olfactory and taste sensory systems

Project duration

June 2019 – December 2021

Project partners

- Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB, Stuttgart

- Fraunhofer Institute for Manufacturing Engineering and Automation IPA, Stuttgart (Coordination)

- Fraunhofer Institute for Process Engineering and Packaging IVV, Freising

- Koniku, CA, USA

Funding

We would like to thank the Ministry of Economic Affairs, Labour and Housing of the State of Baden-Württemberg for funding the project "Biohybrid olfactory and taste sensory systems".

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB