Renewable resources and organic residues – valuable raw materials for biotechnological conversion

Renewable raw materials and residues represent a local, sustainable source for the production of high-quality products. Residues are produced in agriculture and also in industrial processes. Usually the desired component is embedded in a complex matrix of other natural substances and must be removed from it.

Holistic use of all components thanks to a wide spectrum of methods

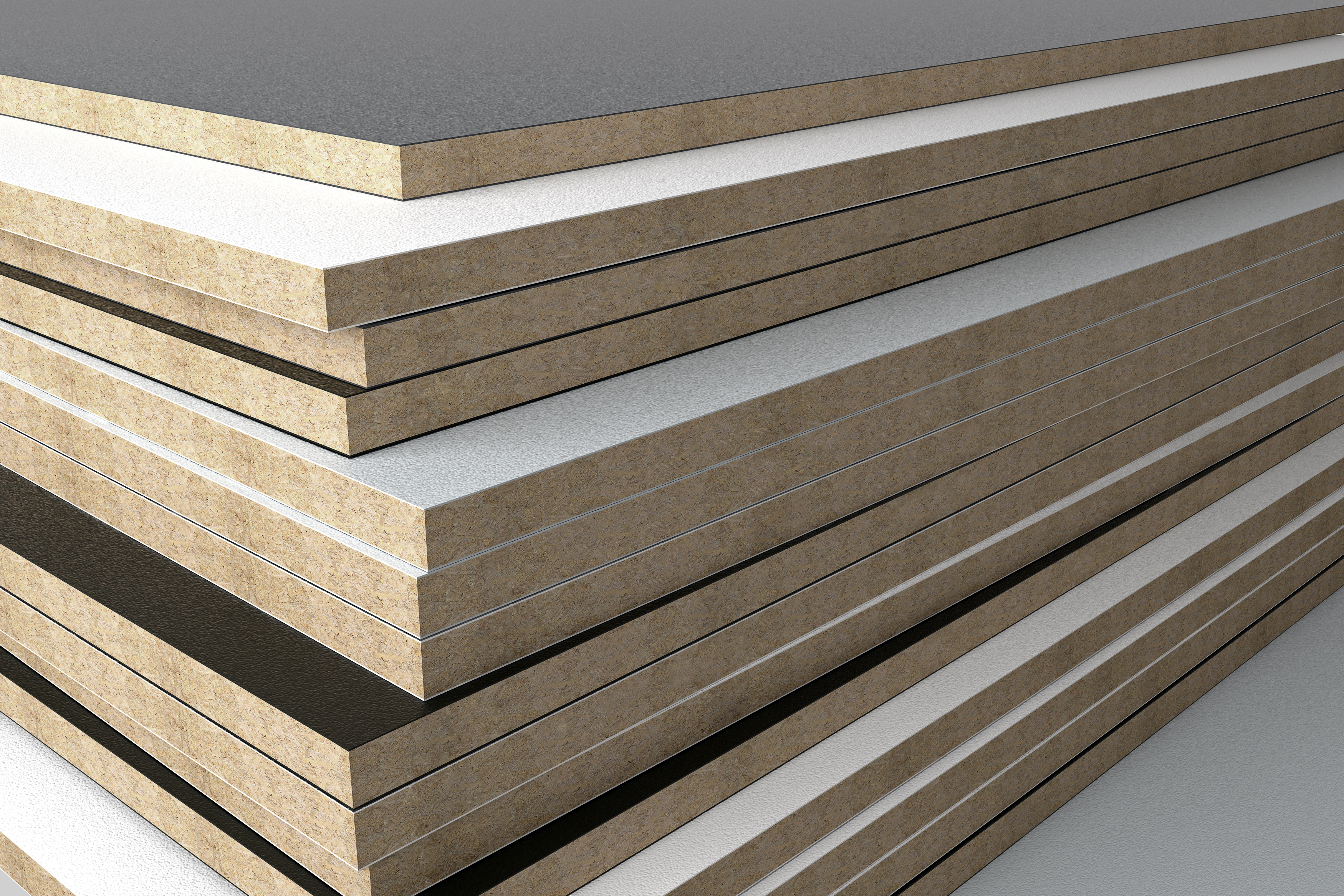

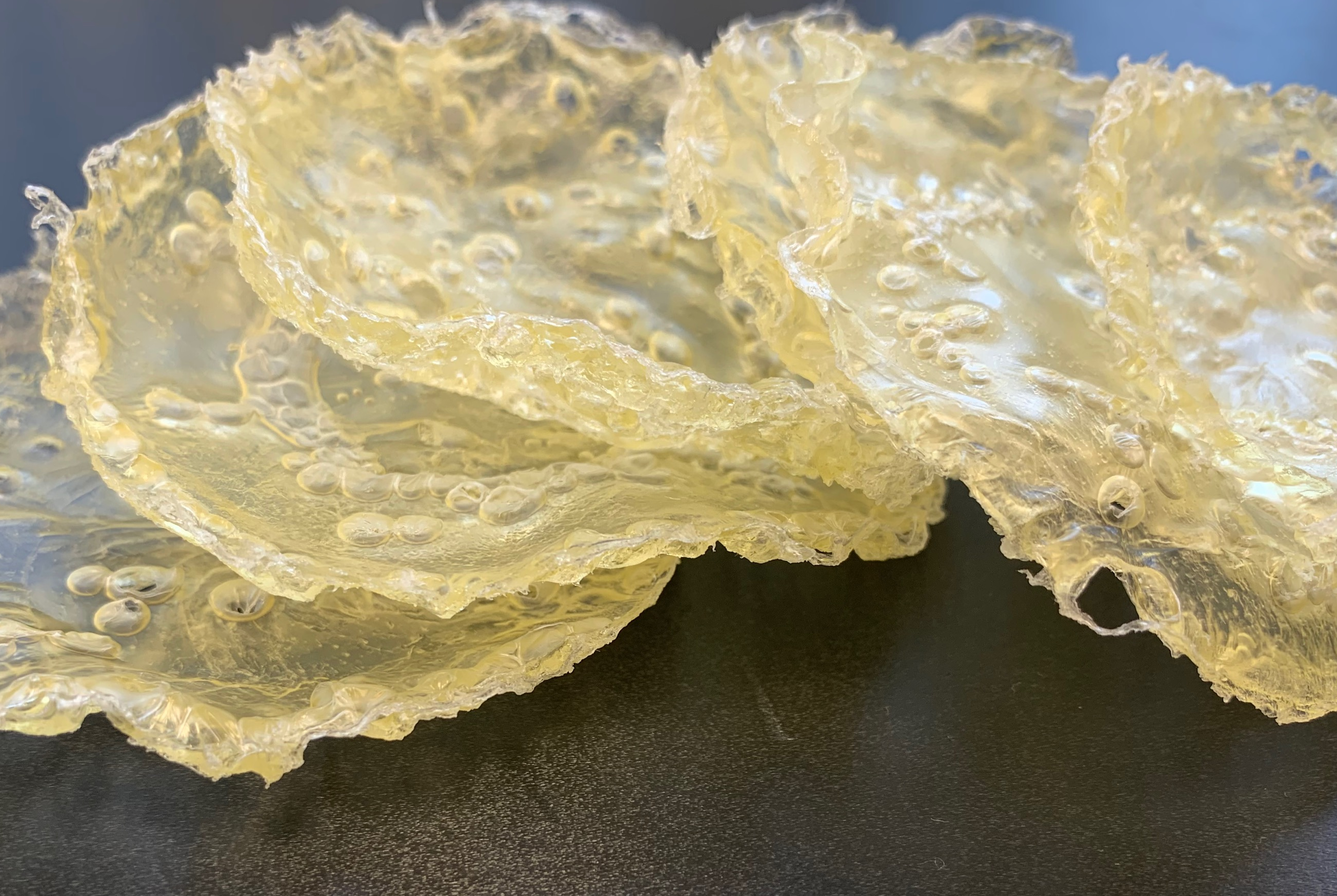

Our working group pursues the goal of a holistic use of all components. Extraction, isolation or pre-treatment are carried out in such a way as to ensure the recovery or use of all substances while minimizing the flow of by-products. This starts with a comprehensive analysis of the various ingredients. Based on the composition and linkage of the desired substance in the substrate, we decide which tool from our repertoire is to be used for processing. The range of our portfolio includes the application of chemical-physical methods for the fractionation of substrates containing lignocellulose and chitin, for example, through to the enzymatic cleavage of organically bound phosphate.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB