Plastics: fossil or biobased? Both!

Synthetic or petroleum-based polymers offer significant advantages that have benefited mankind for more than a century. It is therefore hardly surprising that more than 90 percent of the polymers produced worldwide are based on crude oil. However, in addition to the advantages they offer, their disadvantages are now becoming increasingly apparent, including the depletion of fossil resources, pollution of the world's oceans and increased CO2 emissions caused by the combustion of non-degradable plastics.

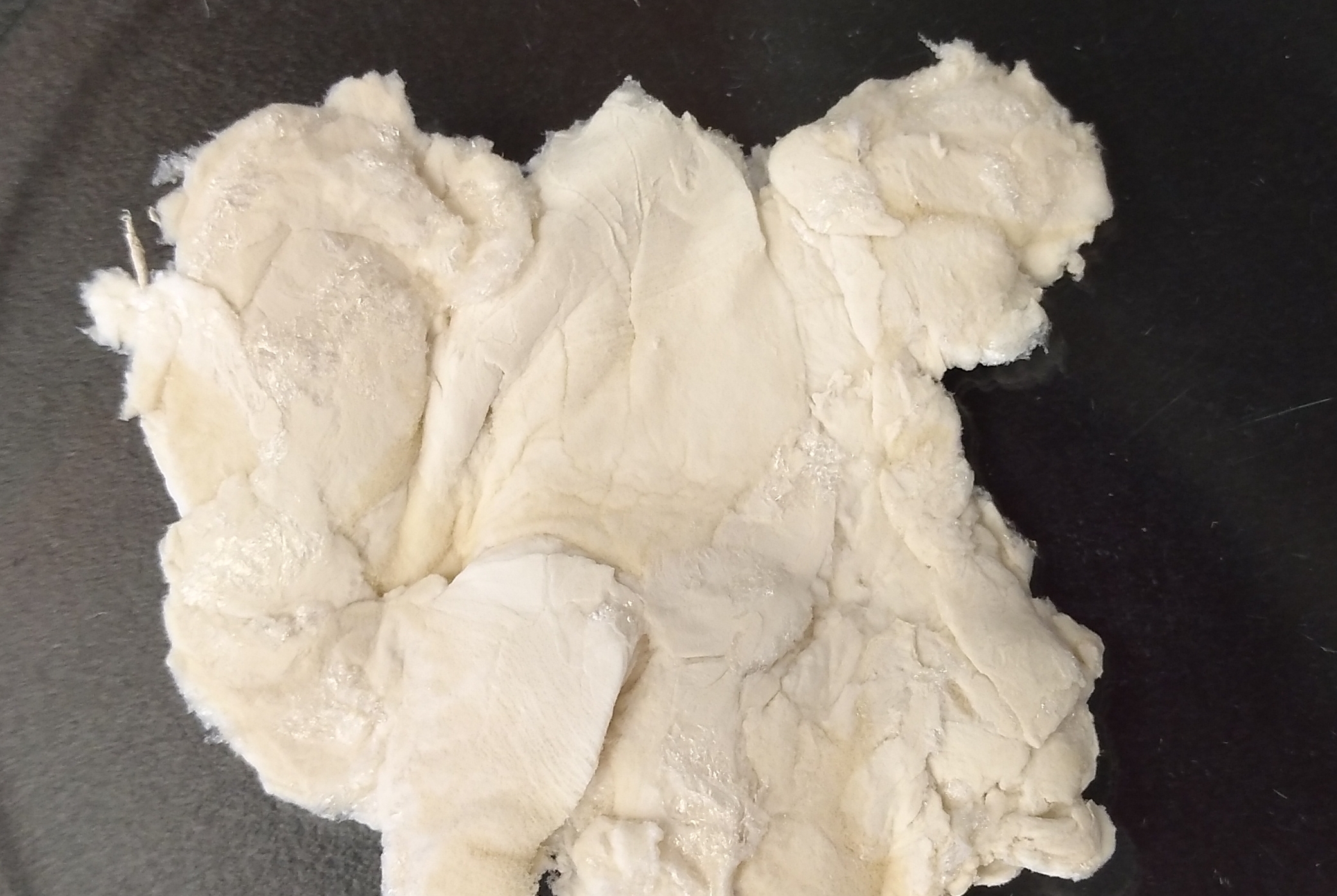

New approaches therefore aim to significantly increase recyclability, for example through the increased use of monomaterials. Despite these efforts, however, alternative and complementary approaches are also required to meet the aforementioned challenges. This circumstance, as well as climate change and increased environmental awareness, has directed the focus towards plastics made from biogenic raw materials. Biobased plastics are mostly biodegradable, biocompatible and can be produced CO2-neutrally.

Biodegradable polymers are in particular high demand when plastics are required for direct use in the environment, for example in agricultural films. These simply decompose over time and leave no traces of microplastics. The aspect of biocompatibility plays a part especially in medical and cosmetic applications.

At Fraunhofer IGB, we contribute significantly to the development of novel biobased plastics by designing and optimizing processes for the production or purification of various biobased polymers and biopolymers.

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB

Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB